Description

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Specification

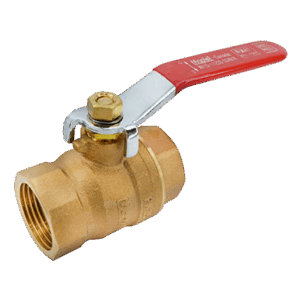

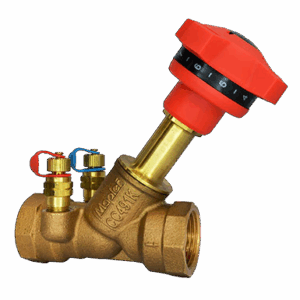

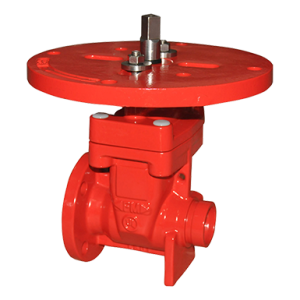

Valve:

Static pressure: 2500 kPa / 360 psi

Ambient temperature: -20°C to +50°C / -4°F to +122°F

Media temperature: -20°C to +120°C / -4°F to +248°F

Material:

– Housing: Forged brass ASTM C37700

– Flow Unit: Glass-filled polymer

– Stem: Brass

– Ball valve: Nickel-plated brass

– Seals, stem: Dual teflon seals and EPDM O-rings (field

repairable)

– Seals, ball: Teflon seals with EPDM O-rings

– End connections: Brass

Rotation: 0°-90°

Maximum close-off pressure: DN15 to DN25: 350 kPa / 50 psi

DN32 to DN65: 300 kPa / 40 psi

DN80 (only NPT): 500 kPa / 70 psi

Shut-off leakage: ANSI / FCI 70-2 2006, Class III / IEC 60534-4,

Class III

End connections1

: Fixed female ISO or NPT

GENERAL SPECIFICATIONS

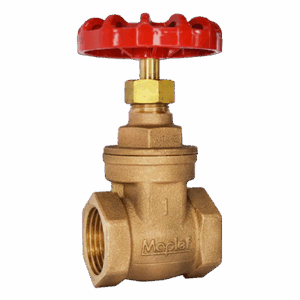

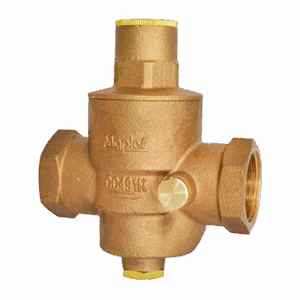

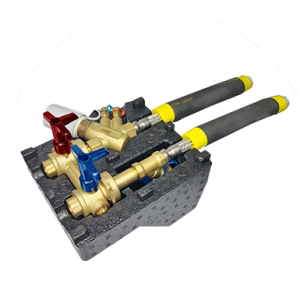

1. ACTUATED CONTROL VALVE -MAPLEF 3-WAY VALVE

1.1. Contractor shall install control valves where indicated in drawings.

1.2. Control valve shall include a universal mounting plate.

1.3. Control valve shall include blow-out proof stem and valve stem shall be seviceable

without removing valve from line.

1.4. Valve housing shall be permanently marked to show A, B and AB for mixing or

diverting configuration.

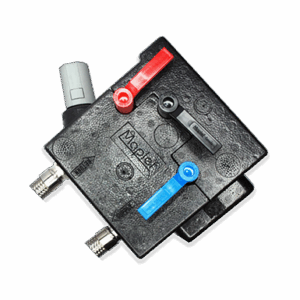

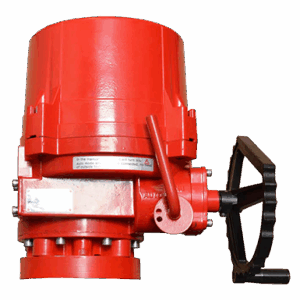

2. VALVE ACTUATOR – MAPLEF MB

2.1. Actuator shall be rated to minimum IP22.

2.2. Actuator shall be driven by 24V AC/30V DC or 230V AC, and shall depending on

actuator choice accept 2-10V, 4-20mA, 3-point floating or 2-position control signal.

2.3. Actuator shall have visible indication of stroke position.

2.4. Actuator shall provide minimum torque for full shut-off position of A.

2.5. Optional auxiliary switch versions shall be available on all control types.

2.6. Manual override shall be possible.

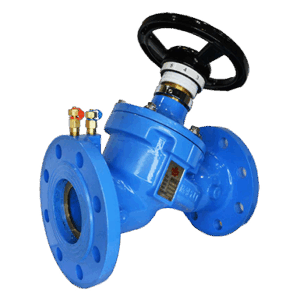

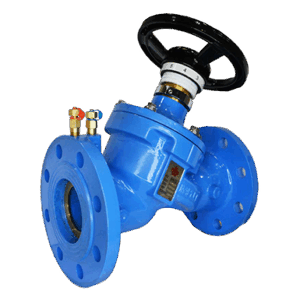

3. VALVE HOUSING

3.1. Valve housing shall consist of forged brass C37700 rated at no less than 2500 kPa (360

psi) at 120°C (+248°C).

3.2. Valve shall include a glass-filled polymer ball-insert to make flow control equal

percentage; a minimum 25 unique Kv valves shall be available.

3.3. Valve shall withstand a close-off pressure of at least 300 kPa (40 psi).

3.4. Valve ball shall consist of chemically nickel-plated brass and ball stem shall consist of

brass.

3.5. Indentification tag shall be avilable; tag shall be indelibly marked with Kv, model

number and location; tag shall be aluminum