Description

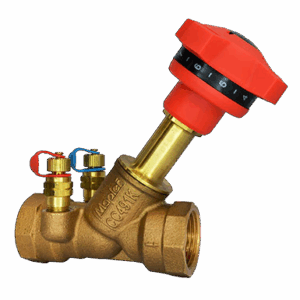

Maplef Red Series – Pressure Independent Control Valves The Maplef Red series comprises a range of pressure independent, two-way control valves designed for modulating operation. These valves are compatible with both digital and analog input signals, accepting 0(2)-10V, 3-point float- ing, or ON/OFF control. Each valve is equipped with an adjustable maximum flow rate setting while maintaining full actuator stroke, ensuring accurate flow limitation and hydraulic balancing of the connected coil or zone. Ideal for use in fan coil units, variable air volume (VAV) systems, and chilled ceiling applications, the Maplef Red series supports both heating and cooling control. The series is available in three valve housing types: Maplef A, Maplef AB, and Maplef ABV.

Features

FEATURES / CHARACTERSTICS

Static Pressure: 2500 kPa / 360 psi

End connections1 : A/AB: Fixed female ISO or NPT,

ABV: Union end connection in

brass alloy ISO or NPT

Housing taps: AB/ABV: 1/4” ISO.

Control Characteristic: Linear(may be converted to

equal % on actuator)

Shut-off leakage: ANSI / FCI 70-2 2006, Class IV / IEC 60534-4, Class IV

Stroke: 20 mm / 3/4” insert: 3.4 mm / 0.13 in

40 mm / 1½” insert: 5.2 mm / 0.2 in

Flow Range : 20 mm / 3/4” insert : 0.0103-0.736 l/sec (0.163-11.7 GPM

40 mm / 1 1/2” insert: 0.240-1.29 l/sec (3.81-20.4 GPM)

Control range: 1: 1000 / IEC 60534

Rangeability : 100:1

Turn down ratio : 100:1

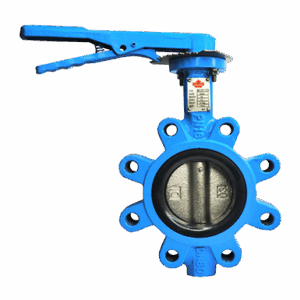

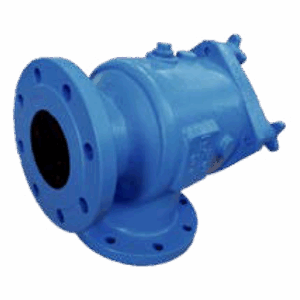

Fully Lugged Design, Wafer Type, Gear Operated

Epoxy Coated, Replaceable Liner, EPDM Lined

Suitable to mount between PN16 Flanges

TEMPERATURE :

Ambient temperature :

+1ºC to +50ºC (+34ºF to +122ºF)

Media temperature2 :

-20ºC to +120ºC (-4ºF to +248ºF)

MAXIMUM CLOSE OFF/ OPERATIONAL PRESSURE :

Max Close off Pressure: 800 kPa / 116 ps

Max. Operational ΔP: 800 kPaD / 116 psid

Specification

- PRESSURE INDEPENDENT DYNAMIC CONTROL VALVES – MAPLEF RED

- 1.1 Contractor shall install the pressure independent dynamic control valves where indicated in the project drawings.

- 1.2 Valve shall be an electronic, dynamic, modulating, 2-way, pressure independent control device.

- 1.3 The pressure independent dynamic control valve shall accurately regulate flow, independent of system pressure fluctuations.

- 1.4 The valve’s maximum flow setting shall be adjustable to 41 discrete positions, tailored to the specific valve size.

- 1.5 Valve housing shall be permanently marked to indicate the direction of flow.

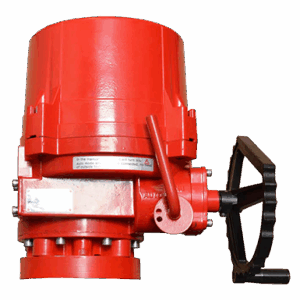

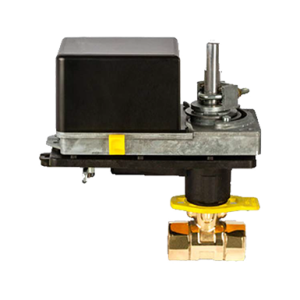

- VALVE ACTUATORS – MAPLEF SERIES

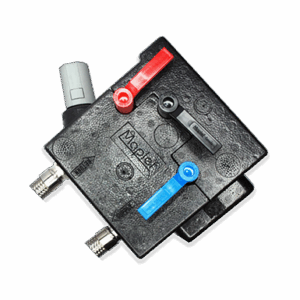

Multiple actuator options are available for use with Maplef Red valves, offering flexible control signal compatibility and high-performance operation. All actuators are designed for precise control and ease of installation.

2.a. Maplef MFT Actuators

- 2.a.1 Actuator housing shall be rated to IP54, including upside-down mounting.

- 2.a.2 Actuator shall be driven by 24V or 230V AC, and shall depending on actuator choice accept 0-10V DC or ON/OFF control signal.

- 2.a.3 Actuator shall use full stroke and provide full authority.

- 2.a.4 Actuator shall have visible indication of stroke position.

- 2.a.5 Failsafe function shall be available on all version.

2.b. Maplef MFN Actuators

- 2.b.1 Actuator housing shall be rated to IP54. 360° mounting shall be acceptable.

- 2.b.2 Actuator shall be driven by 24V AC/DC and shall depending on actuator choice accept 0(2)-10V DC, 3-point floating or 2-position control signal.

- 2.b.3 Actuator shall use full stroke and provide full authority.

- 2.b.4 Actuator shall have visible indication of stroke position.

- 2.b.5 Feedback signal equal to control signal shall be standard on modulating versions.

- 2.b.6 Optional auto stroke function shall be available on modulating version.

- 2.b.7 Override shall be possible.

- 2.b.8 Optional bus version, with choice of BACnet or Modbus, shall be available. Bus version shall provide remote setting and control of actuator.

2.c. Maplef MFNP Actuators

- 2.c.1 Actuator housing shall be rated to IP54. 360° mounting shall be acceptable.

- 2.c.2 Actuator shall be driven by 24V AC/DC and accept 0(2)-10V DC control signal.

- 2.c.3 Actuator shall use full stroke and provide full authority.

- 2.c.4 Actuator shall have visible indication of stroke position.

- 2.c.5 Optional auto stroke function shall be available on modulating version.

- 2.c.6 Electrical override shall be possible.

2.d. Maplef MFNR Actuators

- 2.d.1 Actuator housing shall be rated to IP54. 360° mounting shall be acceptable.

- 2.d.2 Actuator shall be driven by 24V AC/DC or 110V/230V AC, and shall depending on actuator choice and accept 0(2)-10V DC, 3-point floating or 2-position control signal.

- 2.d.3 Actuator shall use full stroke and provide full authority.

- 2.d.4 Actuator shall have visible indication of stroke position.

- 2.d.5 Manual override shall be possible.

2.e. Maplef MFNJ Actuators

- 2.e.1 Actuator housing shall be rated to IP54. 180° mounting shall be acceptable.

- 2.e.2 Actuator shall be driven by 24V AC/DC, and shall accept 0-10V DC control signal.

- 2.e.3 Actuator shall use full stroke and provide full authority.

- 2.e.4 Actuator shall have visible indication of stroke position.

- 2.e.5 Feedback signal of 0-10V DC shall be standard.

- 2.e.6 Failsafe version shall be standard.

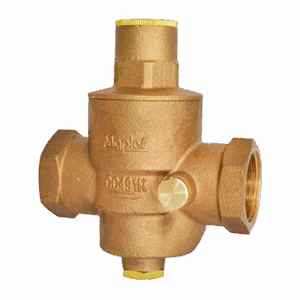

- VALVE HOUSING

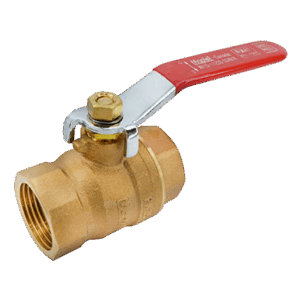

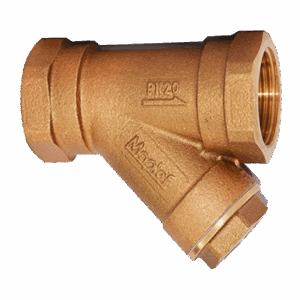

3.a. Maplef A

- 3.a.1 Valve housing shall consist of forged brass ASTM CuZn40Pb2 or DZR ASTM CuZn36Pb2As, rated at no less than 2500 kPa (360 psi) static pressure at +120°C (+248°F).

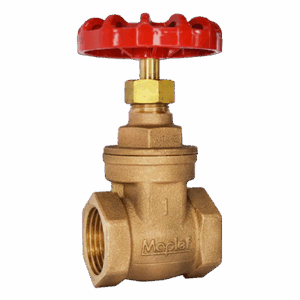

3.b. Maplef AB

- 3.b.1 Valve housing shall consist of forged brass ASTM CuZn40Pb2 or DZR ASTM CuZn36Pb2As, rated at no less than 2500 kPa (360 psi) static pressure at +120°C (+248°F).

- 3.b.2 Pressure/temperature test plugs for verifying accuracy of flow performance shall be available for all valve sizes.

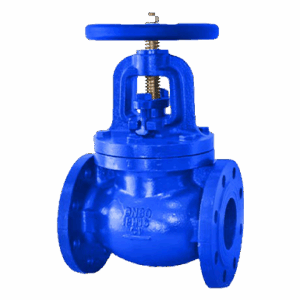

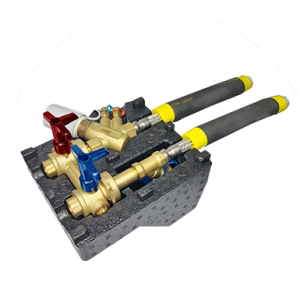

3.c. Maplef ABV

- 3.c.1 Valve housing shall consist of forged brass ASTM CuZn40Pb2, rated at no less than 2500 kPa (360 psi) static pressure at +120°C (+248°F).

- 3.c.2 Valve ball shall consist of chemically nickel-plated brass (ASTM CuZn40Pb2).

- 3.c.3 Pressure/temperature test plugs for verifying accuracy of flow performance shall be available for all valve sizes.