Description

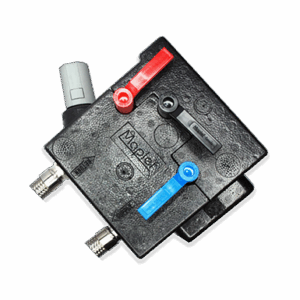

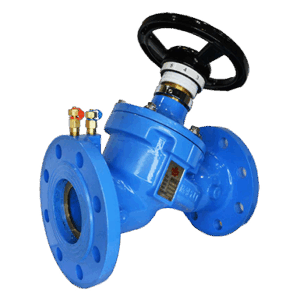

The MSM series is a range of self-balancing dynamic flow control valves that are pressure independent and 2-way and ready to accept digital or analog input signals. Each valve has an adjustable maximum flow rate setting to enable flow limitation to and balancing of the coil or zone which the valve is controlling.

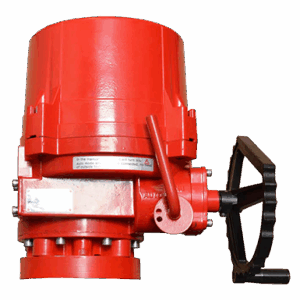

All MSM actuators are microprocessor based with a self-calibrating feature. The MSM actuator range includes standard incl. feedback, failsafe and BACnet. All MSM actuators are programmable and with display. The MSM actuators accept analog 0(2)-10V DC or 0(4)-20mA as well as digital 3-point floating or 2-position input signals and work with selectable control mode of Linear flow, Equal percentage, Linear rotation or Linear signal.

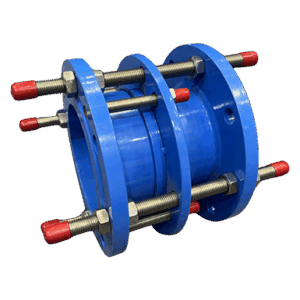

The larger range of MSM-valves are all designed for double flange connection. They are available in four different valve body sizes. All shall have snap connection for fast mounting of actuator.

Features

FEATURES / CHARACTERSTICS

Valve:

Static pressure : 4000 kPa / 580 psi

Ambient temperature : -10°C to +50°C / +14°F to +122°C

Media temperature : -20°C to +120°C / -4°F to +248°C

Material:

Housing and covers : Ductile iron ASTM A395 Grade 60-40-18

Metal components (internal) : Stainless steel

Stem seal and O-rings : EPDM

Diaphragm : Hydrogenated acrylonitrile-butadiene-rubber

Stroke : 2160° (MSM.6: 3600°)

Maximum close off pressure : 800 kPa / 116 psi

Maximum operational ΔP : 800 kPaD / 116 psid

Maximum allowable operating pressure : 1600 kPaD / 232 psid

Control characteristic : Linear flow (may be converted to equal%,

linear rotation or linear signal on actuator)

Control range : 1:1000 / IEC 60534

Rangeability : >100:1

Turn down ratio : 228:1

Shut-off leakage : ANSI / FCI 70-2 206 / IEC 60534-4 – Class IV

Flow rate range : 1.48-76.8 l/sec / 23.4-1220 GPM

End connection : Universal flange connections which can be used

with both ISO and ANSI flanges. Mounting kits are

not supplied by Maplef

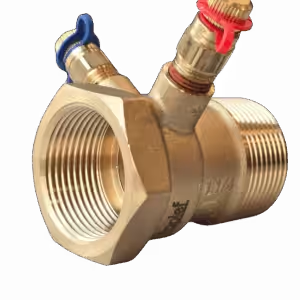

Body taps : 1/4” ISO

Maplef Actuator:

Maplef MSM.0.0.0.3, MSM.0.0.0.4, MSM.0.0.0.5 (with BACnet) and MSM.0.0.0.6 (with BACnet)

actuators1

Supply voltage : 22-26V AC, 50/60 Hz or 22-26V DC

Type : Electrical, Bi-directional synchronous motor

Power consumption : 12VA

For failsafe versions : 25VA (peak)

Control signal : Analog 0(2)-10V DC or 0(4)-20mA and digital

3-point-floating or 2-position

Resolution : 1:1000 (0-10V analog) and 1:800 (2-10V analog)

Feedback : Linear signal Auto (equal to analog control signal),

0-10V DC, 2-10V DC or 4-20mA

Control mode : Linear flow, Equal percentage, Linear rotation or Linear

signal

Failsafe function : Yes (on MSM.0.0.0.4 and MSM.0.0.0.6)

Manual override : Yes

Position indicator : No

Operation time : MSM.3-5: 190 sec (from closed to fully open valve)

MSM.6: 317 sec (from closed to fully open valve)

Ambient temperature : -10°C to +50°C / +14°F to +122°F

Humidity rating : 5..95% rH, no condensation

Protection : IP54 including upside-down mounting

CE conformity : EN 60730, class II

Housing material : UL94 V0-rated plastic

Programming : Programming of all settings on interface with buttons and

display or via BACnet

Cable : Fixed, 5 wires x 0.80 mm2, halogen free, 1 meter Fixed,

5 wires x AWG18, halogen free, 3 ft

Additional for BACnet versions:

Fixed, 3 wires x 0.80 mm2, halogen free, 1 meter

Fixed, 3 wires x AWG18, halogen free, 3 ft

Calibration : Automatic at startup

Valve-actuator coupling : Easy snap coupling

BACnet device profile : BACnet Application Specific Controller (B-ASC) type

server

BACnet protocol : BACnet Master Slave/Token passing (MS/TP)

BACnet baud rates supported : 9600, 19200, 38400 and 76800

BACnet services (BIBBS) supported : DS-RP-B, DS-WP-B, DM-DDB-B, DM-DOB-B and DM-DCC-B

Specification

1.1. Contractor shall install pressure independent dynamic control valves where indicated in drawings.

1.2. Valve shall be an electronic, dynamic, modulating, 2-way pressure independent control device.

1.3. Valve shall accurately control flow, independent of system pressure fluctuation.

2. VALVE ACTUATOR

2.1. Valve-actuator coupling shall be snap coupling for fast mounting and de-mounting.

2.2. Actuator housing shall be rated to IP54 including upside-down mounting.

2.3. Actuator shall be driven by a 24V AC/DC motor and shall accept 0(2)-10V, 0(4)- 20mA, 3-point floating or 2-position control signal.

2.4. Actuator control mode shall be selectable to Linear flow, Equal percentage, Linear rotation or Linear signal.

2.5. Actuator shall be capable of providing linear feedback signal to the control system. Feedback signal shall be selectable to Auto (equal to input signal), 4-20mA, 0-10V DC or 2-10V DC.

2.6. Automatic calibration of valve position shall be standard.

2.7. Actuator shall include buttons for external programming of all settings.

2.8. Actuator display showing current valve flow, maximum valve flow, input signal,

feedback signal, operational direction and control mode shall be standard.

2.9. Optional failsafe versions shall be available. Failsafe versions shall be able to operate valve to either open(max. setting) or closed position from any position in case of power failure.

2.10. Optional BACnet versions shall be available. BACnet versions shall provide remote setting and control of actuator.

3. VALVE HOUSING

3.1. Housing shall consist of ductile iron ASTM A395 Grade-40-18 rated at no less than 4000 kPa (580 psi) static pressure and +120°C (+248°F).

3.2. Housing shall be permanently marked to show direction of flow.

3.3. Housing shall be for installation between flanges.

3.4. Dual pressure/temperature test plugs for verifying accuracy of flow performance shall be standard on all valve sizes.

3.5. Identification label according to PED-requirements shall be available for all valves.

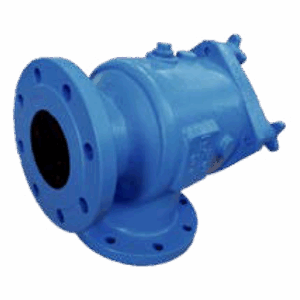

4. FLOW REGULATOR / AUTOMATIC BALANCING UNIT

4.1. Maximum flow setting shall be adjustable to minimum 51 different settings within the range of the valve size.

4.2. Flow regulation unit shall be manufactured of stainless steel and hydrogenated acrylonitrile-butadienerubber and shall be capable of controlling flow within ±5% of controlled flow rate of ±2% of maximum flow rate.

4.3. Flow regulation unit shall be accessible for change-out or maintenance.